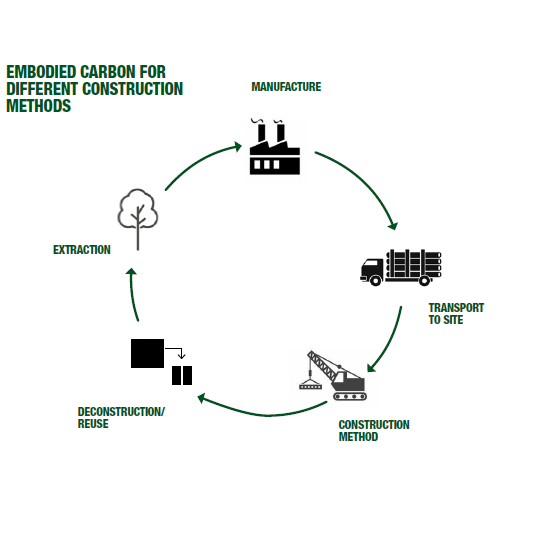

The embodied carbon of a building is the sum of carbon emitted in the

- Extraction

- Manufacture

- Transport to Site

- Construction

- Deconstruction/ End of Use.

of all the materials and products that go into it.

The RICS have established an accurate means of calculating embodied carbon with the RICS Whole Life Carbon for the Built Environment. PH Ribbon, an add on to the PHHPP uses the same methodology and provides a useful assessment tool at the design stage.

Achieve more with less.

If you can achieve the same aims using less material, then that is the first step to lowering the embodied carbon of a building. It can also have the added benefit of reducing construction costs. This can be done by.

Building with a good form factor. A building with a lower form factor will use less material to enclose the same internal area.

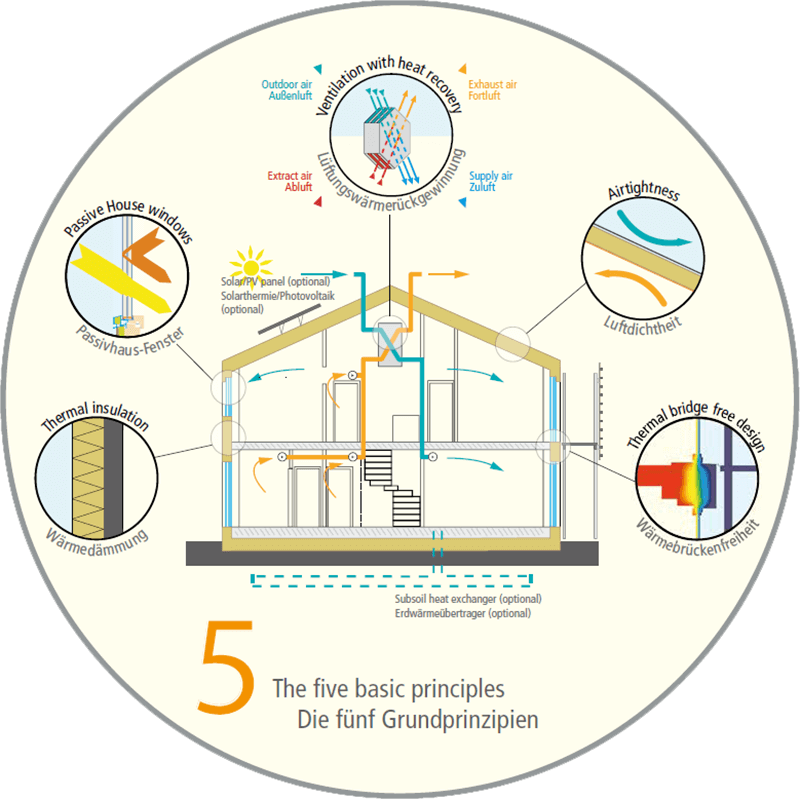

Optimising performance through good design. This means not over engineering the structure or the building services, such as the heating system.

Avoiding waste. A lot of construction materials can go to waste. Good scheduling and management can avoid a lot of this. Employing Modern Methods of Construction (MMC) can also be a means of reducing waste.

Where there is a choice of materials or products, choosing the one with a lower embodied carbon over its lifetime.

The embodied carbon of materials can change over their lifetime and depending on how they are used.

Timber, for example has a negative embodied carbon in its raw state, but if at the end of its life it is burned rather than recycled much carbon is released back into the atmosphere. Despite this, it remains one of the materials with the lowest embodied carbon over its lifetime.

Concrete does have a high amount of embodied carbon, but for certain elements (i.e foundations) it is the only appropriate material for the task. If it is exposed to the atmosphere concrete will absorb some carbon over its lifetime reducing its overall embodied carbon. It can also be easily broken up and recycled into aggregate at the end of a buildings life.

Oil based materials tend to have a high amount of embodied carbon and do not have the potential for recycling at the end of a buildings life.

To meet and exceed the RIBA 2030 Challenge of 625KgCO2e/m² we need to both achieve more with less and choose the most appropriate materials for the task and with the lowest embodied carbon.